Home

- Driven by Innovation, Built for Efficiency, Designed to Last

YOUR PARTNER FOR CONSTRUCTION AND WAREHOUSE MACHINERY

What makes us different

- Sustainable innovation

Your advantages at Mueller Machinery

Cost efficiency you can rely on

Our company is committed to delivering cost-efficient solutions that maximize value without compromising on performance.

Fuel Consumption reduction

Advanced engine technologies, optimized fuel combustion, and stringent emission control system

Environmentally conscious

Sustainable material production practices that

support a greener future.

Quality production

Machinery engineered for peak

performance with minimal resource consumption.

Specialization That Drives Project Success

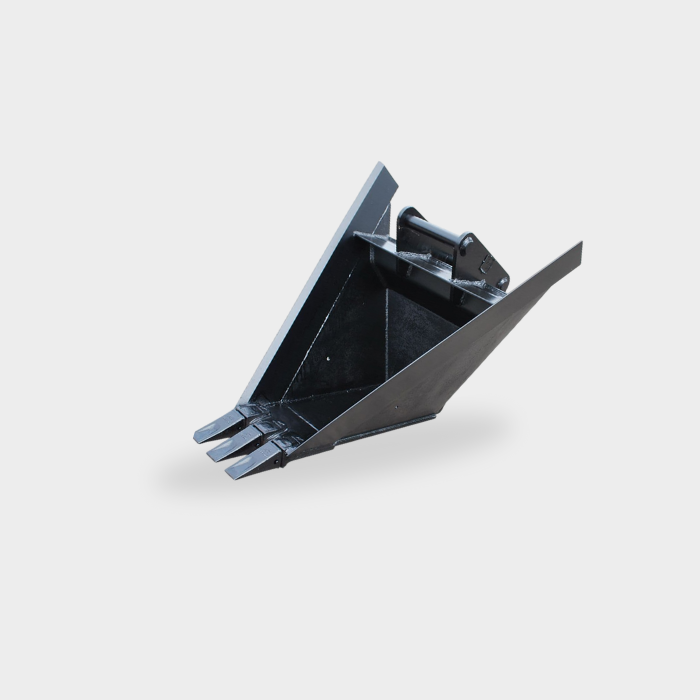

- Durability that stands the test of time

Müller Machinery’s equipment is crafted with high-quality materials for superior strength and reliability. Designed to withstand extreme conditions, our machines offer rust and corrosion resistance, easy maintenance, and long-lasting performance.

Structural integrity

Sturdy materials

Crafted with high-quality materials designed to withstand extreme conditions.

High precision manufacturing

State-of-the-art manufacturing

Engineered with precision for superior strength and reliability.

Rust & corrosion proof

Long lasting

Special coatings and treatments for enhanced resistance to rust and corrosion.

Maintenance

Longevity made easy

Designed for easy maintenance, reducing downtime and extending equipment lifespan.

Adaptability for Every Industry and Project

Built tough for extreme conditions

and demanding workloads.

Optimized for efficient

handling and logistics in fast-paced environments.

Versatile equipment suited for precision in compact spaces.

Robust machines engineered to tackle the toughest demolition tasks with ease.

Services

Service areas

Ready to elevate your projects? Whether it’s diesel, electric, or lifting machinery, we have the right solution for you. Contact us today and let’s get your equipment needs covered!

Diesel Construction Machinery